Introduction

Regular maintenance is essential for keeping an inverter generator running smoothly, extending its lifespan, and preserving consistent power quality. Because inverter generators rely on precise electronics and efficient combustion systems, proper care ensures reliability during camping trips, RV travel, or home power outages. This guide explains the most important inverter generator maintenance steps users should follow. For a broader technical overview, see the main Inverter Generator Guide and lifespan-focused content such as Do Inverter Generators Last Longer?.

Why Maintenance Matters

Maintaining an inverter generator offers major benefits:

- longer engine life

- stable power output

- reduced noise

- better fuel efficiency

- lower chance of failure during emergencies

- protection for sensitive electronics

With regular care, most inverter generators provide reliable service for many years, especially when combined with smart load management as discussed in Inverter Generator Fuel Consumption.

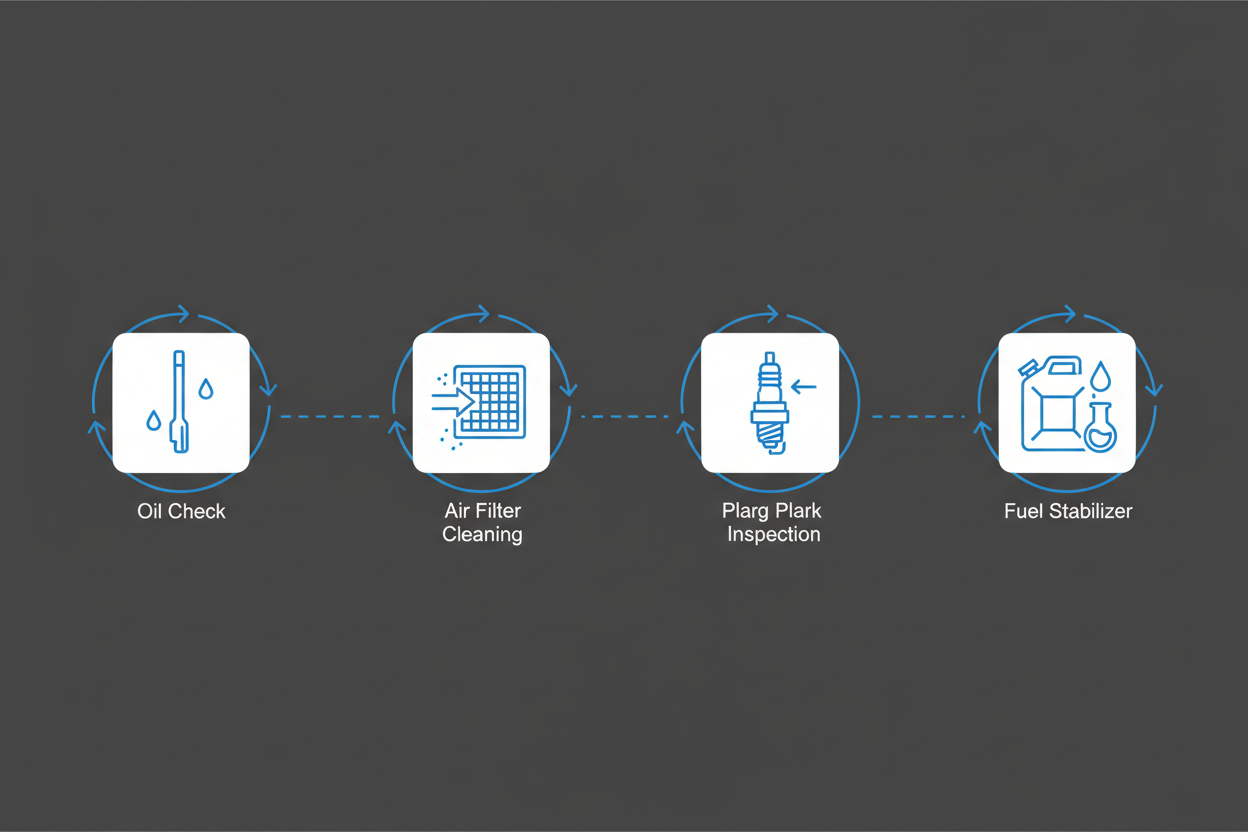

Essential Maintenance Tasks

1. Check and Change Engine Oil Regularly

Oil is critical for engine health. General recommendations include:

- checking oil every 20–30 hours

- replacing oil every 50–100 hours (or per the manual)

Low oil levels may trigger the low-oil shutdown feature, preventing damage but interrupting power, which can be disruptive during long-runtime operation.

2. Clean or Replace the Air Filter

A clogged air filter reduces engine performance and increases fuel consumption. For dusty environments such as campsites and RV travel:

- clean the filter after every trip

- replace it whenever it appears worn or excessively dirty

A clean air filter supports efficient combustion, smoother operation, and more stable output for electronics.

3. Inspect and Maintain the Spark Plug

A worn or fouled spark plug can cause:

- hard starting

- rough idle

- poor fuel efficiency

Inspect the spark plug roughly every 100 hours and replace it annually—or sooner if performance drops—especially on generators used frequently for RV or home backup duty.

4. Use Fresh Fuel and Stabilizers

Old gasoline can clog small passages and create starting problems. Best practices include:

- using fresh, clean fuel

- adding fuel stabilizer for seasonal or long-term storage

- avoiding gasoline that sits in the tank for several months

Propane does not degrade, making it ideal for long-term emergency preparedness in dual-fuel models. For runtime expectations with different fuels, see Inverter Generator Fuel Consumption.

5. Run the Generator Monthly

To keep internal components lubricated and electronics active:

- run the generator for 10–15 minutes each month

- enable ECO mode and apply a light, steady load

This simple exercise helps prevent internal corrosion, protects seals, and keeps the carburetor cleaner for the next real outage or trip.

6. Keep the Exterior Clean and Ventilated

Dust and debris can block ventilation and cause overheating. Wipe down the casing regularly and make sure cooling vents remain clear of obstructions, especially when running near walls, fences, or RV compartments.

7. Store Properly When Not in Use

For long-term storage:

- drain gasoline or run the carburetor dry

- disconnect the spark plug or disable ignition

- store the unit in a cool, dry location

- cover it with a breathable generator cover

Proper storage prevents corrosion, moisture buildup, and varnish formation in the fuel system, especially in humid regions.

Maintenance for Dual-Fuel Models

Dual-fuel inverter generators require a few additional checks:

- ensure propane hose connections and seals are tight

- inspect the regulator connection regularly

- keep propane tanks stored upright and secured

- check for leaks using soapy water around fittings

These small steps improve safety and long-term performance when running on propane. For broader fuel strategy, compare options in Dual-Fuel vs Gas Generators.

Signs Your Generator Needs Attention

Watch for warning signs such as:

- difficulty starting

- unusual noise or vibration

- higher fuel burn than usual

- uneven or fluctuating power output

- visible smoke or exhaust changes

- warning lights on the control panel

Addressing issues early prevents more expensive repairs and reduces the risk of failure during critical use, especially when the generator is supporting home backup loads or RV air conditioning.

Conclusion

Inverter generator maintenance is simple but essential. With routine oil checks, air filter cleaning, fuel management, and periodic inspections, your generator will keep delivering clean, stable power for years. Proper care gives you confidence during outages, camping trips, and RV travel.

For complete guidance on performance, runtime, and cost of ownership, explore the full Inverter Generator Guide and related articles such as Inverter Generator Runtime, Inverter Generator Fuel Consumption, and Do Inverter Generators Last Longer Than Traditional Generators?.