Introduction

One of the biggest reasons users choose inverter generators is their long-term durability. Many people ask: Do inverter generators last longer than traditional generators? In most cases, the answer is yes. Lower engine stress, cleaner electrical output, and efficient fuel management all contribute to a longer operating life. This guide explains why inverter generator lifespan is typically superior and how proper maintenance ensures years of reliable performance. For a full overview of inverter technology, visit the Inverter Generator Guide.

Why Inverter Generators Last Longer

Inverter generators use modern engineering that minimizes mechanical wear compared with traditional open-frame models. Key advantages include:

- variable engine speed under light loads

- stable load distribution

- optimized combustion and fuel management

- reduced heat buildup during operation

- clean, digitally regulated sine wave output

Together, these design benefits significantly extend both engine and electronic component lifespan.

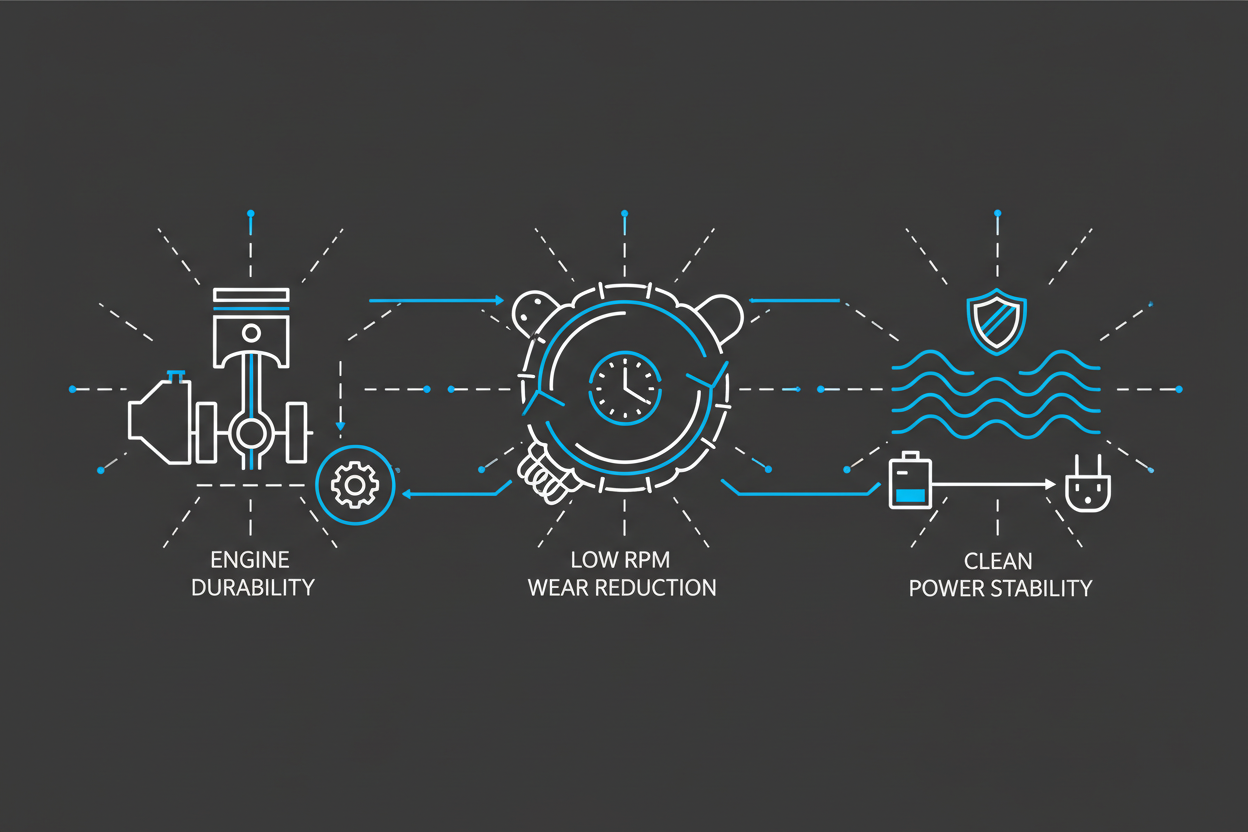

Why Inverter Generators Experience Less Wear

1. Variable RPM Reduces Stress

Traditional generators must run at a fixed 3600 RPM to maintain 60Hz output—even when powering a phone charger. Inverter generators automatically adjust RPM according to load:

- low load → low RPM → minimal wear

- medium load → moderate RPM

- high load → full power only when needed

This reduces mechanical strain and prolongs engine life. For more on how load affects fuel use, see Inverter Generator Fuel Consumption.

2. Cleaner Combustion Means Cleaner Engines

Digital throttle control improves fuel-air mixture, resulting in:

- more complete combustion

- less carbon buildup

- cleaner valves and pistons

- slower oil contamination

Engines stay cleaner internally, reducing long-term maintenance requirements.

3. Less Heat = Longer Component Life

Heat is one of the fastest ways to shorten engine lifespan. Inverter generators run cooler because:

- RPM drops during light load conditions

- enclosed acoustic housing manages airflow efficiently

- optimized exhaust design reduces thermal load

Cooler operation extends the life of internal wiring and electronic components.

4. Cleaner Electricity Protects Internal Circuits

Traditional generators produce “dirty power” with unstable voltage and high THD, stressing:

- AVR boards

- wiring and connectors

- voltage regulators

Inverter generators produce pure sine wave AC, which:

- eliminates surge-related wear

- reduces thermal stress

- keeps output stable during load changes

Cleaner electricity protects the generator itself and the appliances it powers. Learn more in What Is THD in Generators?.

5. Lower Vibration Improves Longevity

Inverter generators use noise-reduction enclosures and internal damping systems, which help:

- prevent bolts and components from loosening

- reduce vibration-related damage

- protect electronics from shock

Lower vibration equals better structural stability over time.

Typical Inverter Generator Lifespan

With proper care, inverter generators often reach:

- 1,000–2,000+ hours for consumer-level units

- 3,000–5,000+ hours for premium models

This is commonly longer than comparable traditional generators, especially in low-to-medium load environments.

Maintenance Factors That Affect Lifespan

To maximize service life:

- change oil at recommended intervals

- clean or replace air filters

- use fresh fuel and stabilizers

- inspect spark plugs regularly

- avoid running at maximum load for long periods

- operate monthly to keep components lubricated

For a complete checklist, see Inverter Generator Maintenance.

When Inverter Generators May Wear Faster

Certain environments can reduce lifespan:

- sustained operation at full load

- extreme high or low temperatures

- lack of routine maintenance

- dusty, sandy, or humid conditions

These conditions accelerate wear but do not reflect typical usage for most homeowners or RV users.

Conclusion

Yes—most inverter generators last longer than traditional generators thanks to variable RPM, efficient combustion, reduced heat, and clean electrical output. With proper maintenance, they provide dependable long-term performance for home backup, camping, and RV travel.

Continue exploring durability, performance, and efficiency topics in the full Inverter Generator Guide.